WES Industries offers a complete line of packaged cogeneration systems for energy management and power cost reduction.

Cogeneration offers significant benefits and is energy-efficient compared with buying electricity from a utility. Cogeneration requires less fuel or electricity to provide the company's power by using waste heat for steam and HVAC needs. Cogeneration provides significant environmental benefits as well. With Cogeneration, total fuel consumption is less than with separate facilities for power and steam; therefore, fewer greenhouse gases are produced. Cogeneration is an excellent example of how business needs and markets encourage investments to reduce costs, generate income, and achieve significant environmental gains. Cogeneration has been proven to be a sound investment. Your pocketbook will benefit, and so will the environment. The WES team will evaluate your facility, engineer the solution, and obtain all required permits for a successful installation.

Applications

- Retail Centers

- Movie Theatres

- Fast Food

- Office Complexes

- Large HVAC Demand Facilities

- Resorts & Hotels

- Airport Common Areas

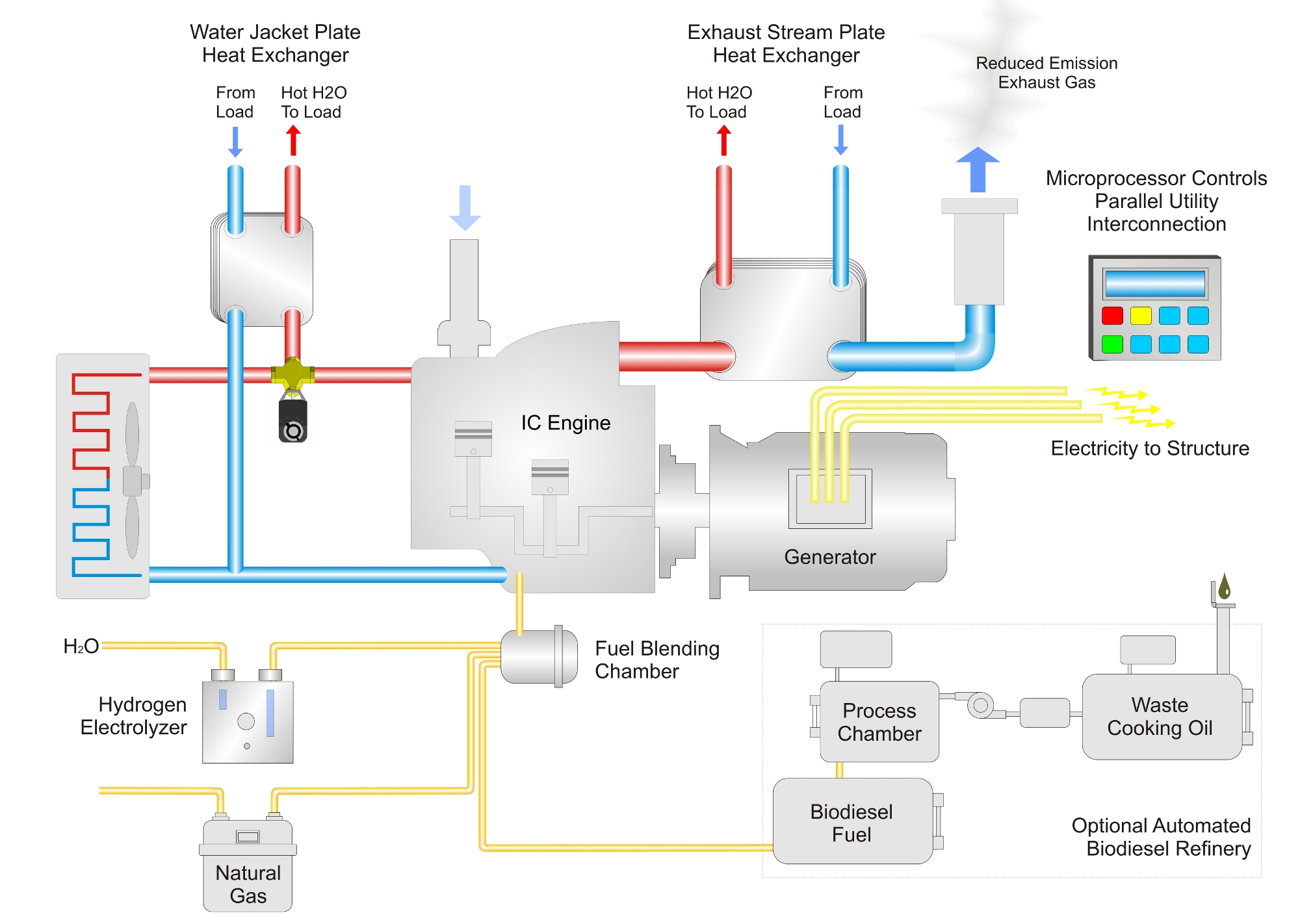

How it Works:

1. Continuous-run generator burns natural gas or biodiesel to produce cheap onsite power.

2. Hydrogen produced through electrolysis is blended with the fuel to reduce CO2 and other emissions.

3. Exhaust is channeled through a heat exchanger for absorption chilling or waste heat recovery.

Cogeneration or combined heat and power (CHP) uses a heat engine [1] or power station to generate electricity and proper heat simultaneously.

Cogeneration is a more efficient use of fuel or heat because otherwise-wasted heat from electricity generation is put to some productive use. Combined heat and power (CHP) plants recover otherwise wasted thermal energy for heating. This is also called combined heat and power district heating. Small CHP plants are an example of decentralized energy.[2] By-product heat at moderate temperatures (100–180 °C, 212–356 °F) can also be used in absorption refrigerators for cooling.

WES Industries, Inc.

Manufactures to meet all NSF, ASTM, ASME, and ANSI requirements.